Cranston, Rhode Island USA – AIM Solder, a leading global manufacturer of solder assembly materials for the electronics industry, is pleased to announce the release of its new low-voiding, no clean solder paste, V9.

Cranston, Rhode Island USA – AIM Solder, a leading global manufacturer of solder assembly materials for the electronics industry, is pleased to announce the release of its new low-voiding, no clean solder paste, V9.

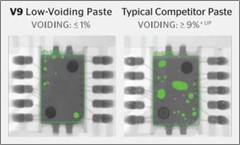

Formulated to solve one of the industry’s most difficult challenges, studies have proven V9 to reduce voiding to as low as 1% on BGA and <5% on BTC components while exhibiting stable print performance on fine feature devices over 12 hours. V9 post-process residue is easily probed and possesses the high SIR values required for high reliability applications. Both REACH and RoHS compliant, AIM’s V9 Low-Voiding No Clean Solder Paste is available in SAC305 T4.

“Our studies show that solder joint reliability and thermal dissipation concerns are significantly reduced with V9,” said Timothy O’Neill, AIM’s Director of Product Management. “V9 is proven to improve production yields and product quality, whether printing 0.50 area ratios or eliminating voiding on BGA and BTC packages.”

Headquartered in Montreal, Canada, AIM Solder is a leading global manufacturer of assembly materials for the electronics industry with manufacturing, distribution and support facilities located throughout the world. AIM produces advanced solder products such as solder paste, liquid flux, cored wire, bar solder, epoxies, lead-free and halogen-free solder products, and specialty alloys such as indium and gold for a broad range of industries. A recipient of many prestigious SMT industry awards, AIM is strongly committed to innovative research and development of product and process improvement as well as providing customers with superior technical support, service, and training. For more information about AIM’s complete line of advanced solder products and global technical services, please visit www.aimsolder.com.