ABSTRACT Implementation of low-temperature solders has been a subject of considerable interest for many consumer electronics manufacturers. Low-temperature solders represent a significant material and process cost advantage over traditional silver-bearing and low-silver alloys. Bismuth-containing alloys enable low-melting temperatures; therefore, if the mission profile of an assembly tolerates the limitations of bismuth-containing low-temperature solders, implementation is favorable.

An overlooked application in implementing low-temperature alloys is rework. The inherent brittleness of bismuth inhibits the manufacturing of fluxed cored wire. An approach to overcome this limitation is to use a high- bismuth solid wire solder with an external flux. This approach introduces challenges associated with implementing new materials and training operators on new rework techniques. Another approach is to use traditional tin (Sn)/ silver (Ag)/ copper (Cu) (SAC) flux cored wire solder to rework low-temperature solder joints. Rework conditions differ from other reflow processes giving considerable process variability due to operator input.

This paper will detail the material properties and rework considerations of using a eutectic tin/bismuth (Sn/Bi) solid wire and SAC305 (Sn96.5/Ag3/Cu0.5) flux cored wire in a rework setting. Solder joint quality of Sn/Bi combined with SAC305, in both through-hole and surface mount applications, will be assessed along with:

a. Diffusion zone of SAC305 and Sn/Bi

b. Shear strength of the resulting solder joints for SAC/SAC, SAC/Sn-Bi and Sn-Bi/Sn-Bi.

The goal of this study is to provide the end-user guidance on rework materials and techniques that can be successfully implemented during the implementation of low-temperature solders and to identify any trouble spots.

INTRODUCTION Low-temperature (LT), high-bismuth solders are being carefully considered to replace SAC305 for several reasons including minimizing component warpage, reducing energy consumption and lowering the cost of solder, substrate, plastics, and other materials. Bismuth is strong, but also brittle and has different mechanical properties than the SAC alloys they are targeted to replace [1]. Despite these drawbacks, consumer electronics that are not subjected to high thermal or mechanical stress may be candidates for low-temperature materials.

Most published studies have overlooked one important consideration when implementing low-temperature alloys: rework and post-assembly attachment processes. This paper will review the issues associated with using low-temperature alloys in the benchtop setting and how these alloys can be implemented or combined with existing processes and materials.

DISCUSSION SAC305 is the PCB assembly standard solder since lead (Pb) was banned from many electronic solders for environmental concerns in 2006. This change forced the implementation of new equipment and materials due to the higher melting temperature of SAC305 versus the tin/lead materials it replaced. One of the main benefits of SAC305 was its compatibility with tin/lead solders. Other elements were considered as part of the Sn/Pb solder replacement, such as indium and bismuth. Both were attractive as they lower the melting temperature of SAC alloys. However, indium was eliminated for supply and cost issues and bismuth was eliminated because when combined with Sn/Pb, a ternary alloy with a melting temperature of 97˚C is formed causing an unacceptable loss of reliability.

Regulations limiting the use of Pb in electronics have effectively removed it from most of the industry’s material supply chain, reinvigorating the interest in bismuth-bearing solder alloys. Given the advantages of a low-melting point alloy, solder manufacturers stay motivated to develop commercially viable products for solder paste, solid alloy, and flux cored wire, but this is not without its challenges.

The physical properties of elemental bismuth are unusual. It has one of lowest thermal and electrical conductivity values of all metals, it is denser as a liquid than a solid, it expands on freezing, and is the most naturally diamagnetic element on the periodic table. Aside from these interesting factors, bismuth’s brittleness is what has the greatest impact on its soldering performance. An alloy with a bismuth percentage above 6% will begin to lose ductility/become more brittle. Brittleness should not be confused with loss of strength; bismuth alloys are strong, but brittle.

Sn42/Bi57/Ag1 is eutectic at 138℃, meaning the liquidus to solidus are coincidental, there is no plastic/pasty state. Adding elements such as silver and indium (In) can improve strength or ductility to high-bismuth alloys, but they will still behave like high-bismuth alloys – strong and brittle. This not only creates issues for PCB assemblers, but it also has a profound impact on the manufacturability of Sn/Bi wire solders. Manufacturing wire solder relies on the ductility of the alloy to allow it to be shaped and formed. When producing flux cored wire, these traits are vital. Flux cored wire is simply a metal tube formed around a die via an extrusion process, subsequently drawn through progressively finer dies. This thin metal tube is prone to cracking and breaking as the equipment relies on a continuous wire to operate correctly. Extrusion presses must be specially outfitted to run high-bismuth wires and run at significantly slower speeds compared to typical SAC alloys. These factors add considerable cost to manufacturing.

Sn/Bi can recrystallize at room temperature therefore this once ductile material can become brittle over time resulting in flux cored wire solder being prone to breaking as it is unspooled. This makes low-temperature alloys poorly suited for fine wire diameters or robotic soldering applications.

Finally, Sn/Bi alloys are slower wetting alloys compared to SAC therefore require more aggressive fluxes to promote spread and flow to facilitate barrel fill and sufficient wetting[2].

These realities leave assemblers using low-temperature solders with three practical options when reworking assemblies: implement high-bismuth low-temperature flux cored wire solder with the material, cost, and availability issues, implement solid high-bismuth wire solder with an external flux, or use SAC flux cored wire in combination with the low-temperature alloy used during the assembly process.

The study will evaluate these three options and provide feedback on the performance characteristics during processing and compare the resulting solder joints using the IPC-610 standard, cross-section evaluation and shear strength testing.

EXPERIMENTAL METHODOLOGY Three rework conditions were followed to compare the performance of high-Bi solders to a SAC305 baseline during rework and post-assembly processes. Condition 1 uses Sn42/Bi57/Ag1 paste and SAC305 flux cored wire. Condition 2 uses Sn42/Bi57/Ag1 paste but is different from condition 1 in that solid Sn42/Bi57/Ag1 wire and external flux is used. Finally, condition 3 employs SAC305 paste and SAC305 flux cored wire for rework. All flux mediums in use are no clean thus, cleaning was not performed.

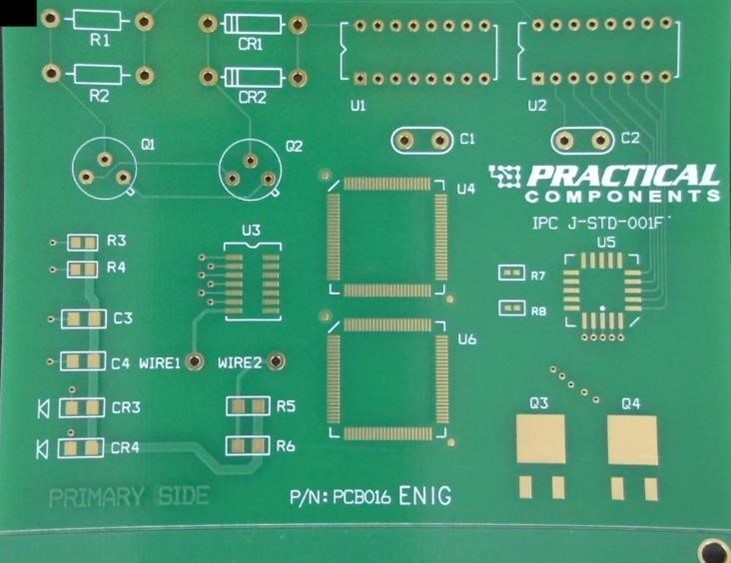

PC016 J-STD-001 REV F/G-LF Solder Training Kit, as seen in Figure 1, was used in this study because of its combination of SMT and PTH component types. The surface finish was ENIG (Electroless Nickel Immersion Gold) with a gold thickness of about 2 microinches and 120 microinches nickel respectively. The assortment of components enables the use of a combination of post-assembly soldering techniques. The following components were tested in this study:

X-section

R1, U1, and CR3.

Shear testing

R3, R4, C3, C4, CR3, CR4, R5, and R6.

Figure 1. PC016-IPC J-STD-001-REV F/G-LF Solder Training Kit

Phase 1 assembly took place in the company Solder Technical Applications laboratory in Juarez, Mexico. A 5 mil, laser cut stencil using PHD stainless steel, mounted at standard tension (~34 N/cm) with apertures designed to promote defects was employed. The stencil design included engineered defects such as BTC apertures combined into one to form solder bridging pads, as indicated by the blue arrows in Figure 2. Also, one of each chip component outlined in red, per Figure 2, was printed using the inverted home-plate design while the second identical component was printed 1:1 with the pad to promote solder balling.

Figure 2. Stencil designed to promote defects

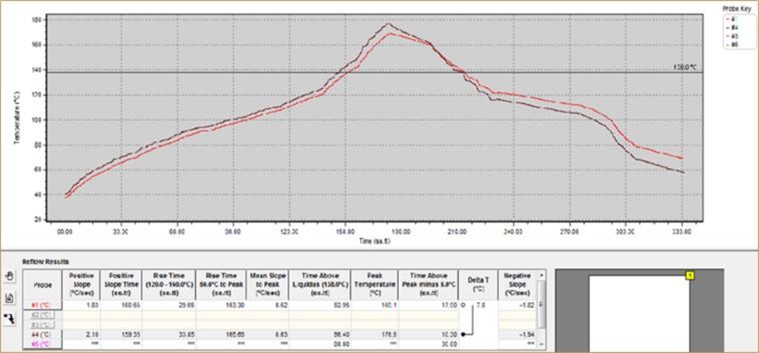

Solder paste was printed using a DEK HORIZON 3AA. The pin-in-paste (PiP) method was used for PTH components. The deposits were inspected for consistent paste volume using a PARMI SIGMA X SPI. After printing, the board was populated using an I-PULSE M10 pick and place machine and the PTH components were inserted manually. The boards were then reflowed with their respective profiles using a HELLER INDUSTRIES, Model: 1936 MK5. A total of eighteen boards were assembled to allow for the experimentation and assessment of various rework techniques. Twelve boards, which are listed in Table 1, were assembled with the company no-clean Sn42/Bi57/Ag1 paste following the reflow profile in Figure 3 with a peak temperature of 170℃.

| Board # | Paste | Peak Reflow (℃) | Rework Wire | Flux |

|---|---|---|---|---|

| 1 | Low Temp | 170 | SAC | Cored |

| 2 | Low Temp | 170 | SAC | Cored |

| 3 | Low Temp | 170 | SAC | Cored |

| 4 | Low Temp | 170 | SAC | Cored |

| 5 | Low Temp | 170 | SAC | Cored |

| 6 | Low Temp | 170 | SAC | Cored |

| 7 | Low Temp | 170 | Low Temp | Liq/Gel |

| 8 | Low Temp | 170 | Low Temp | Liq/Gel |

| 9 | Low Temp | 170 | Low Temp | Liq/Gel |

| 10 | Low Temp | 170 | Low Temp | Liq/Gel |

| 11 | Low Temp | 170 | Low Temp | Liq/Gel |

| 12 | Low Temp | 170 | Low Temp | Liq/Gel |

Table 1. List of materials and peak reflow temperatures used for low-temperature solder assemblies

Figure 3. 170℃ SnBiAg Peak reflow profile

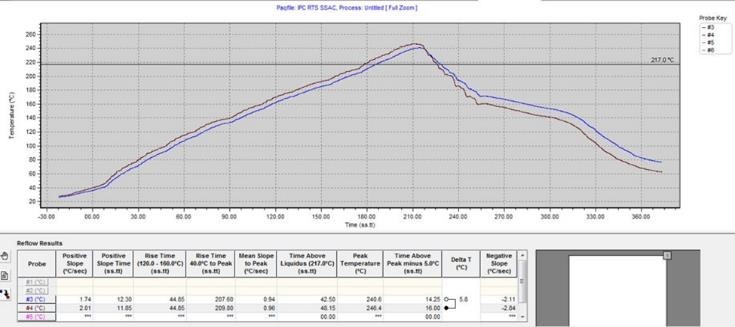

Six boards, listed in Table 2, were assembled using the company no clean SAC305 paste following the reflow profile in Figure 4 with the peak reflow temperature of 246℃.

| Board # | Paste | Peak Reflow (℃) | Rework Wire | Flux |

|---|---|---|---|---|

| 13 | SAC | 246 | SAC | Cored |

| 14 | SAC | 246 | SAC | Cored |

| 15 | SAC | 246 | SAC | Cored |

| 16 | SAC | 246 | SAC | Cored |

| 17 | SAC | 246 | SAC | Cored |

| 18 | SAC | 246 | SAC | Cored |

Table 2. List of materials and peak reflow temperatures used for SAC solder assemblies

Figure 4. 246℃ SnAgCu Peak reflow profile

After assembly, the next phase was simulating various rework/post-assembly processing techniques under each soldering condition. This was conducted at EPTAC Corporation, in Manchester, New Hampshire.

Rework was performed with a soldering iron (Figure 5) with a chisel tip (Figure 6) set to 630˚F/330℃. The company no clean flux cored SAC305 wire was used to rework twelve total boards: six of the twelve assemblies using Sn42/Bi57/Ag1 paste, per condition 1, and six assemblies using SAC305 paste, per condition 3. The remaining six boards assembled using Sn42/Bi57/Ag1 paste were reworked using solid Sn42/Bi57/Ag1 wire combined with the company no clean liquid flux for PTH components and the company no clean gel flux for SMT components, per condition 2.

Figure 5. 246℃ SnAgCu Peak reflow profile

Figure 6. Chisel tip

The second part of this phase comprised of reproducing the rework techniques applied and capturing them on video. This was completed in Essex, England.

Rework Techniques and Tooling

None of the components used in rework were prepped or pretinned prior to being assembled to the board.

PTH

The PTH components were removed by cutting the component leads, applying liquid flux to the remaining solder joints, and removing the components with heated tweezers. The through-hole vias were cleaned with copper braid. Four axial components, two radial caps and one IC was removed from each board.

SMT

The surface mount components were removed with heated tweezers (Figure 7). The pads were prepped for new components by applying no clean liquid flux and solder braid to remove excess solder. No clean rework gel flux was then applied, and a small amount of Sn-Bi solder was applied to prepare for the installation of new components.

Figure 7. Heated Tweezers were used to remove SMT components

Once the pad terminations were prepared and fluxed, the components were placed onto the pads, the solder was reflowed using hot air, and the components were slid onto the molten solder alloy. The process was repeated on the opposite side.

The intentionally designed SMT defects such as bridges on the gull wing components, were reworked by applying gel flux and copper braid, heated with the soldering iron, to wick the solder away. The joints were refluxed with the no clean gel and the low melt alloy was re-applied to verify the joint met the requirements of the IPC J-STD-001 document.

ANALYSIS METHODOLOGY

Cross-section analysis was conducted on one PTH and two SMT components per soldering condition: R1, U1, and CR4, respectively This was done to investigate the impact of the various rework techniques and soldering conditions on intermetallic compound (IMC) formation.

Mechanical shear testing was conducted on SMT components R3, R4, C3, C4, CR3, CR4, R5, and R6 at a constant speed of 0.1mm/s and a shear height of 0.15mm.

RESULTS:

Rework Observations

All the surface mount components were prepared using no clean gel flux and PTH components with no clean liquid flux. It was noted that solid low-temperature solder did not wet the solder iron tip as well as the flux cored SAC305 wire which was not surprising.

The solid Sn/Bi wire worked well with the addition of the application of external flux. The solder joints were visually inspected and met the requirements of IPC J-STD-001. When using solid low-temperature wire, the solder iron tip remained tinned and functional with no degradation of the tip tinning.

When using SAC305 flux cored wire, soldering the smaller size surface mount components proved challenging due to the large wire diameter. Although the joints appeared to have excess solder, they met the wetting requirements according to IPC J-STD-001.

Solder Joint Analysis

Cross-Section Analysis

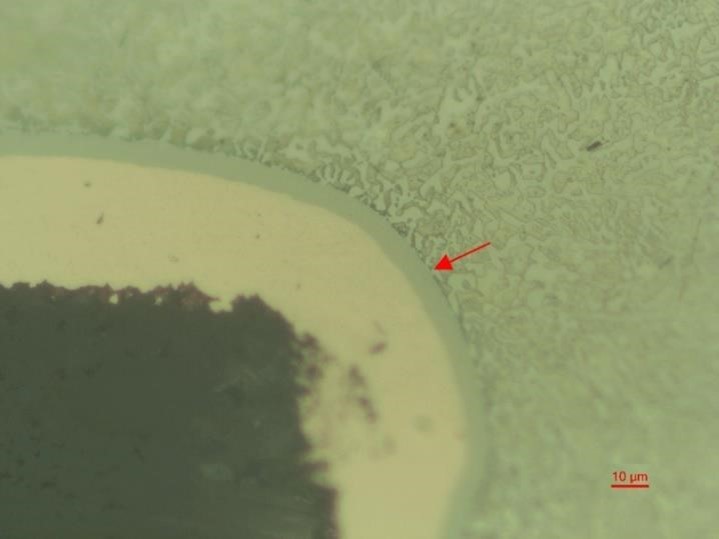

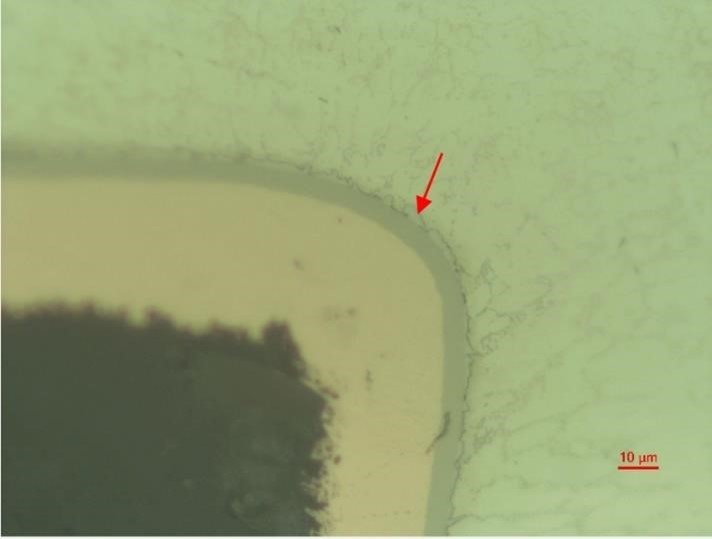

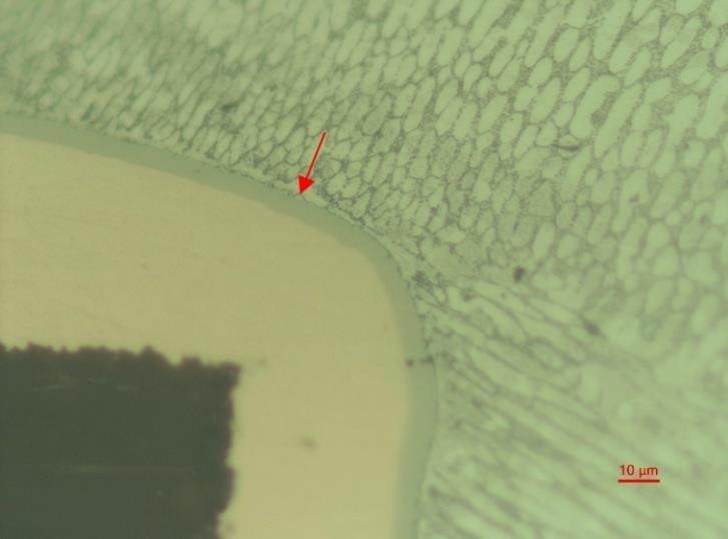

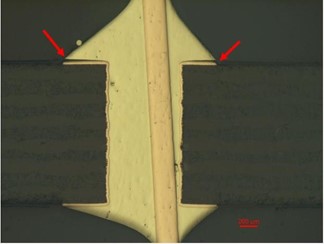

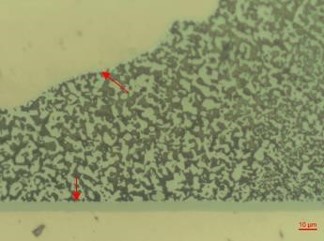

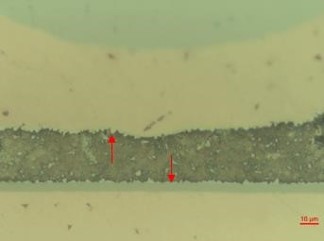

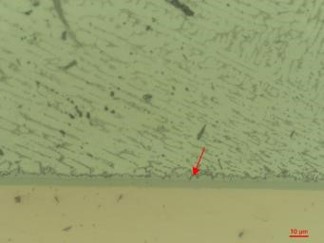

The cross-section analysis showed typical IMC formation for all the reworked joints. Figures 8-15 display the typical IMC formation per each soldering condition. Figures 8-11 display PTH component, R1, while Figures 12-15 display SMT component CR4.

Figure 8. R1 PTH component assembled with Sn42/Bi57/Ag1 paste reworked with solid Sn42/Bi57/Ag1 wire and external flux

Figure 9. R1 PTH component assembled with Sn42/Bi57/Ag1 paste reworked with SAC flux cored wire

Figure 10. R1 PTH component assembled with SAC paste reworked with SAC flux cored wire

Figure 11. Fillet lift on U1 PTH component assembled with Sn42/Bi57/Ag1 paste reworked with SAC flux cored wire

Almost all the PTH joints have 100%-barrel fill, however, the fillet lifting phenomena on the topside was observed at R1 of board #2 and U1 of board #1 in SAC/LT case as seen in Figure 11. Fillet lift is a common occurrence when using high-bismuth alloys and is not a defect per IPC-610 standard.

On the SMT components, each IMC is well formed showing good wetting on the pads of the PCB and terminations of components. Figures 12-15 display the IMC formation per soldering condition on SMT component CR4.

Figure 12. CR4 component assembled with Sn42/Bi57/Ag1 paste reworked with solid Sn42/Bi57/Ag1 wire and external flux

Figure 13. CR4 component assembled with Sn42/Bi57/Ag1 paste reworked with SAC flux cored wire

Figure 14. CR4 component assembled with SAC paste reworked with SAC flux cored wire, pad side

Figure 15. CR4 component assembled with SAC paste reworked with SAC flux cored wire, component side

In conclusion, rework has been successfully performed, with no observed defects under all test conditions. All solder joints were acceptable per IPC-610 inspection criteria.

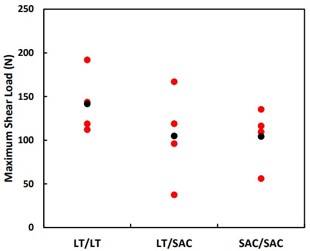

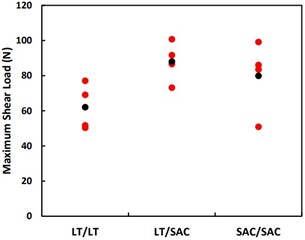

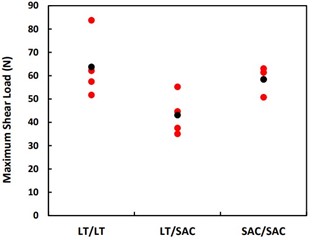

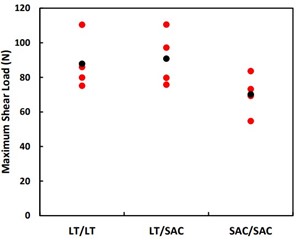

Shear Testing

Shear test results for components C3/C4, CR3/CR4, R3/R4, and R5/R6 are shown in Figures 16-19.

Figure 16. Shear force for C3/C4 components for the 3 test cells (red = each test, black = average)

Figure 17. Shear force Vs extension relationship for CR3 and CR4 components

Figure 18. Shear force for R3/ R4 components for the 3 test cells (red = each test, black = average)

Figure 19. Shear force for R5/ R6 components for the 3 test cells (red = each test, black = average)

Each soldering condition performed comparably during shear testing per component type. The variation seen within a single soldering condition, no matter the component, can be attributed to the variable nature of rework. Rework is a manual operation, and the quality of a reworked solder joint is highly influenced by operator input. Even the most expert operator producing acceptable solder joints will have variation in their work. Shear testing did not show a clear outlier in mechanical performance over the three soldering conditions. The low shear force values in Figure 15 can be attributed to inconsistent volumes of solder being applied to the joint, which is a result of the manual operation of rework.

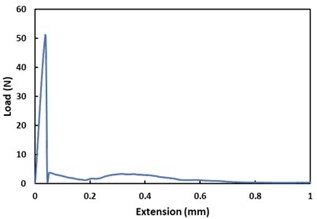

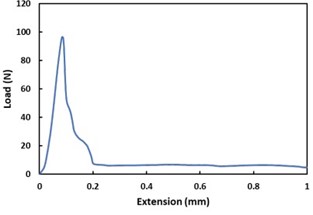

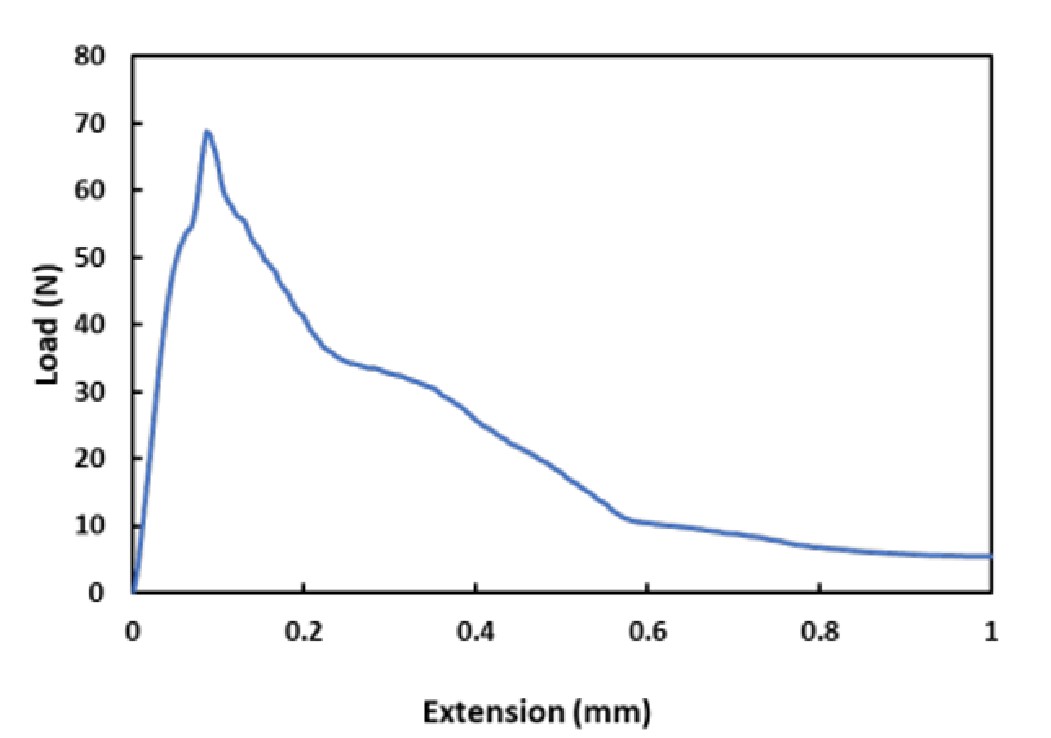

Figures 20-22 display the typical shape seen in a shear force versus extension relationship for each soldering condition/test cell. The results of component R5 are shown in the following Figures. The high-bismuth (LT reworked with LT) curve seen in Figure 20 is sharp, indicating that the alloy can withstand load (N) but breaks abruptly due to its brittle properties.

Figure 20. Typical shear force versus extension relationship for component printed with LT paste reworked with LT wire and external flux (R5)

Figure 21. Typical shear force versus extension relationship for component printed with LT paste reworked with SAC flux cored wire (R5)

Figure 21 shows the curve of the LT paste reworked with SAC flux cored wire, displaying a less sharp curve and greater extension (mm), indicating it is more ductile than the LT paste reworked with LT wire and external flux (Figure 20).

Finally, Figure 22 illustrates how the SAC paste reworked with SAC flux cored wire extends the greatest but withstands less load (N) before extension compared to the LT paste reworked with SAC flux cored wire (Figure 21).

Figure 22. Typical shear force versus extension relationship for component printed with SAC paste reworked with SAC flux cored wire (R5)

CONCLUSIONS

Low-temperature alloys used in SMT and PTH processes can be successfully reworked using low-melting temperature solid wire and external flux as well as with flux cored SAC305 wire solder. The low-temperature solder behaves differently in processing than the SAC equivalent but was not an obstacle in creating quality solder joints. LTS Solid wire with external flux will require qualification of an appropriate flux for the application requirements. As with any externally applied flux, residue, and reliability characteristics due to processing techniques must be considered.

The resulting solder joints met IPC Class 1, 2, 3 solder joint criteria. The shear test results were inconsistent due to the variable nature of rework, but trends are visible. SAC solder joints were more ductile than Bi bearing counterparts. This is not unexpected. SAC+Sn/Bi solder joints shear results reflected the properties of the combined alloys. The operator in this study was an IPC hand soldering certification instructor with decades of experience. Even with a highly qualified operator, results are variable. This highlights the importance of operator training in implementation of low-temperature rework.

When using SAC305 flux cored wire solder, the process was like existing SAC/SAC rework processes. No special considerations were noted other than to consider the use of finer wire diameters when reworking smaller components.

Low-temperature flux cored wire solder was NOT included in this study due to the prohibitive cost to the end-user and limited availability.

FUTURE WORK

Based on the outcomes of this study, more testing has been scheduled. The effect of low-temperature alloys on soldering iron tip life and equipment will be evaluated. In theory, lower operating tip temperature will extend solder tip life, offering another cost saving opportunity for low-temperature implementation. In addition, low-temperature alloy flux residue was noticeably darker than the SAC alloy residue. Analysis indicated the presence of bismuth oxide which is an aesthetic concern. Future testing will include the ease of cleaning these dark residues in both the assembly and rework setting.

REFERENCES

[1] D. Witkin, “Influence of Microstructure on Mechanical Behavior of Bi-Containing Pb-Free Solders” IPC APEX Expo, San Diego, CA, USA, 2013.

[2] H. Osgood, D. Geiger, R. Pennings, C. Biederman, J. Jiang, J. Bernal, “Low-Temperature SMT Solder Evaluation” IPC APEX Expo, San Diego, CA, USA, 2019

AUTHORED BY

Tim O’Neill, Jen Fijalkowski, Carlos Tafoya, Yuan Xu, Steve Hrcek

AIM Solder, Montreal, Quebec, Canada

Leo Lambert

EPTAC Corporation, Manchester, NH, USA

Bob Willis

Chelmsford, Essex, England

S’ad Hamasha, Ph. D.

Auburn University, Auburn, AL, USA

*PRESENTED AT SMTAI 2022

ACKNOWLEDGEMENTS

The authors would like to thank the Applications Lab Team at AIM, Andres Lozoya, Angel Lopez and Ruben Sanchez for their patience and dedication. We would also like to acknowledge the input and guidance of Yuan Xu of the Metallurgy Department at AIM whose knowledge helped make this study possible.