Cranston, Rhode Island USA – AIM Solder, a leading global manufacturer of solder assembly materials for the electronics industry, is pleased to announce their participation in the upcoming NEPCON China and SMTA China East taking place from July 19th – 21st in Shanghai. AIM will highlight their newest halogen-free no clean solder paste, H10.

During SMTA China East, AIM Solder’s Dillon Zhu will present on assembly challenges and solutions for M0201, 08005, and micro/miniLED. Zhu will describe how processing solder paste using Type 6 and finer powders requires a thorough examination of current materials, equipment, and processes to ensure success. He will share practical information about the implementation requirements of Type 6 pastes as well as lessons learned in assisting clients in preparing for an inevitable change in how PCBs are assembled today and in the future.

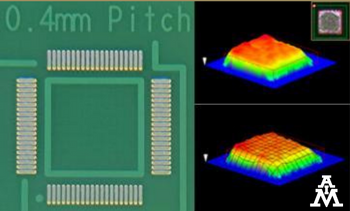

AIM Solder’s halogen-free, no-clean solder paste, H10, offers exceptional fine feature printing, is capable of transfer efficiency >90% on area ratios of 0.50, and has a stencil life >8 hours. H10’s powerful wetting characteristics eliminate NWO (HiP) defects and improve pad coverage on all surface finishes. It also reduces voiding on BGA, BTC, and LGA and offers enhanced electrochemical reliability on all low stand-off devices. Fit for automotive, LED and aerospace assemblies, H10 no-clean solder paste is robust, stable, and easy to implement.

To discover all of AIM’s products and services, visit the company at NEPCON China in the miniLED demo line and SMTA China East for more information and to speak with one of AIM’s knowledgeable staff members, or visit www.aimsolder.com.

Headquartered in Montreal, Canada, AIM Solder is a leading global manufacturer of assembly materials for the electronics industry with manufacturing, distribution and support facilities located throughout the world. AIM produces advanced solder products such as solder paste, liquid flux, cored wire, bar solder, epoxies, lead-free and halogen-free solder products, and specialty alloys such as indium and gold for a broad range of industries. A recipient of many prestigious SMT industry awards, AIM is strongly committed to innovative research and development of product and process improvement as well as providing customers with superior technical support, service, and training. For more information about AIM’s complete line of advanced solder products and global technical services, please visit www.aimsolder.com.