With silver costs reaching historic highs—nearly triple what they were just one year ago—the economics of solder alloy selection have shifted dramatically. SAC305, long considered the lead-free industry standard, now carries an even steeper price premium. Its 3% silver content now contributes to the majority of its cost. In contrast, REL61, a proven low-silver alternative, offers comparable or superior performance at a significantly lower price.

As metal prices across the board continue to climb, silver stands out as the most volatile and expensive element. This makes now the ideal time for manufacturers to reevaluate their alloy choices.

For decades, silver has played a central role in modern solder alloy design. Its inclusion in solder, particularly in tin-silver-copper (SAC) alloys like SAC305, improves mechanical strength, enhances thermal fatigue resistance, and promotes better wetting. But as silver prices continue to rise at unprecedented rates, the cost of these benefits is becoming harder to justify, especially when proven, lower-cost alternatives like REL61 exist.

The Cost of Silver and Its Effect on Alloy Price

While all metals have experienced price increases over the past year, silver’s spike has been among the most extreme. As of January 2026, silver prices are nearly three times higher than they were just one year ago. This change has had a significant impact on the cost structure of alloys containing silver.

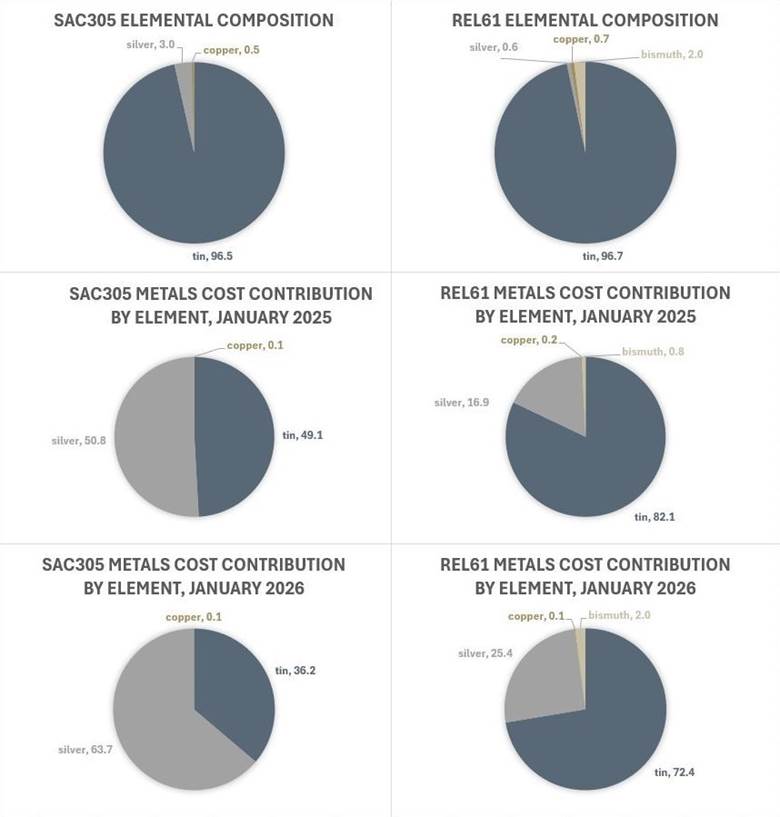

The following pie charts illustrate the elemental composition of each alloy as well as the contribution of each element to the metals cost of each alloy in January 2025 and now in January 2026.

These charts offer a clear visual representation of how much silver drives up total alloy cost, even when it makes up just a small percentage of the total composition.

Let’s break this down:

- Although SAC305 contains only 3% silver, that silver alone makes up nearly two-thirds of the total metals cost in the alloy.

- REL61, by contrast, contains only 0.6% silver. In this alloy, silver represents just one-quarter of the metals cost, even at today’s inflated prices.

Historically, SAC305 has always cost more than REL61 due to its higher silver content.

- One year ago, the cost of the metals used to produce SAC305 was approximately 1.67 times higher than the metals in REL61.

- Today, that difference has grown to about 2x.

As silver prices continue to rise, this gap is likely to widen even further.

Why REL61 Is the Smarter Choice Now More Than Ever

REL61 is not new. It has been widely adopted for over a decade by leading global manufacturers in automotive, LED lighting, consumer electronics, and more. Backed by extensive internal testing and independent third-party validation, REL61 consistently meets or exceeds the performance of SAC305 across key metrics, including:

- Thermal cycling

- Drop shock resistance

- Wetting performance

- Process stability

Its low-silver formulation offers a compelling cost advantage, while the inclusion of bismuth enhances mechanical strength and reduces soldering temperatures. REL61 also contains no phosphorus, making it especially well-suited for selective soldering processes where nozzle degradation is a concern.

REL61 is available in bar, solid and cored wire, and paste, providing flexibility for every application and assembly method.

The Bottom Line

There has never been a better time to make the switch. The cost of silver is higher than ever, and it is significantly inflating the total cost of SAC305. REL61 offers a proven, cost-effective, and high-performance alternative that continues to gain industry-wide traction.

You can reduce costs without sacrificing quality. In fact, you may even gain performance advantages. And with REL61’s widespread availability and application versatility, there’s no reason to wait.

Make the switch to REL61 today, before silver costs climb even higher.