REL61™

LEAD-FREE SOLDER ALLOY

Features

- Cost Saving SAC Alloy

- Enhanced Reliability Versus SAC and All Low/No-Silver Alloys

- Improved Thermal Cycling Performance

- Improved Wetting Versus All Low/No-Silver Alloys

- Aids in AOI First Pass Yields

- Proven Tin Whisker Mitigation

- Lower Process Temperature

- Complies with IPC J-STD-006

REL61 Lead-Free Solder Alloy

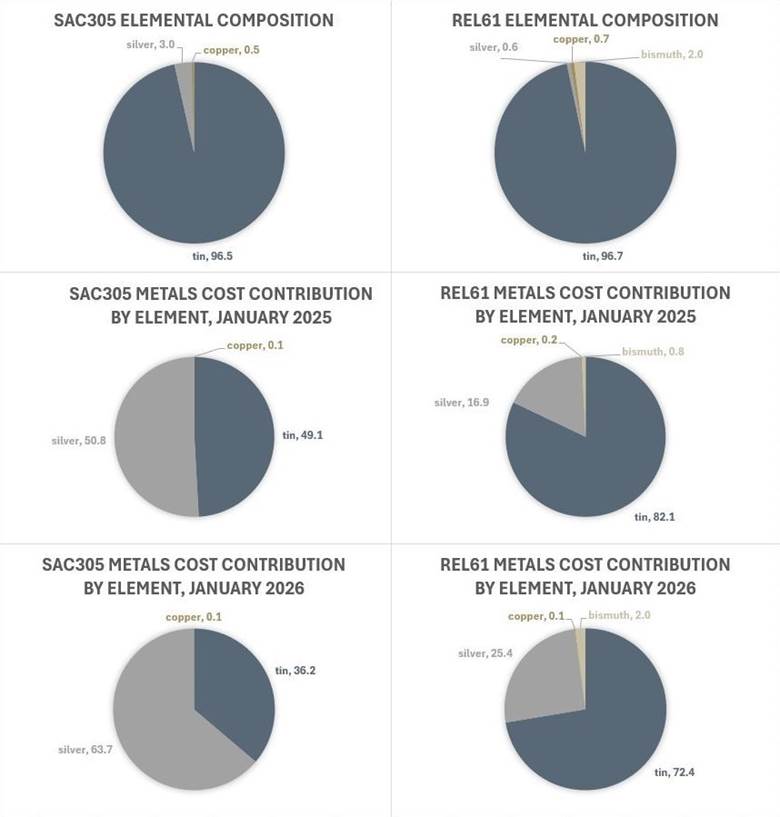

REL61™ is a low-cost alternative to SAC alloys with reliability and performance characteristics equal to or greater than SAC305 and other low/no-silver solders.

REL61 has proven to reduce the formation of tin whiskers and outperform SAC alloys in thermal shock, vibration and drop shock reliability testing. REL61 exhibits superior spread, flow and wetting in production testing versus silver-free alloys.

REL61 is available in bar solder, solder wire, and solder paste.

- Ideal for automotive, telecom and consumer assemblies

- Smooth uniform appearance in SMT soldering

- Lower reflow/solder pot temperature

- Reduces solder dross in selective and wave soldering applications

- For use in lead-free process only

| Composition | Melting Temperatures (℃) | Peak Reflow Temperature (℃) | Cost Level |

|---|---|---|---|

| Sn/Cu/Ag/Bi | 208°C -215°C | 230°C | $$ |

If the document you need is not listed below, please contact your local AIM Customer Service Rep or contact us to request the document.

Related Content

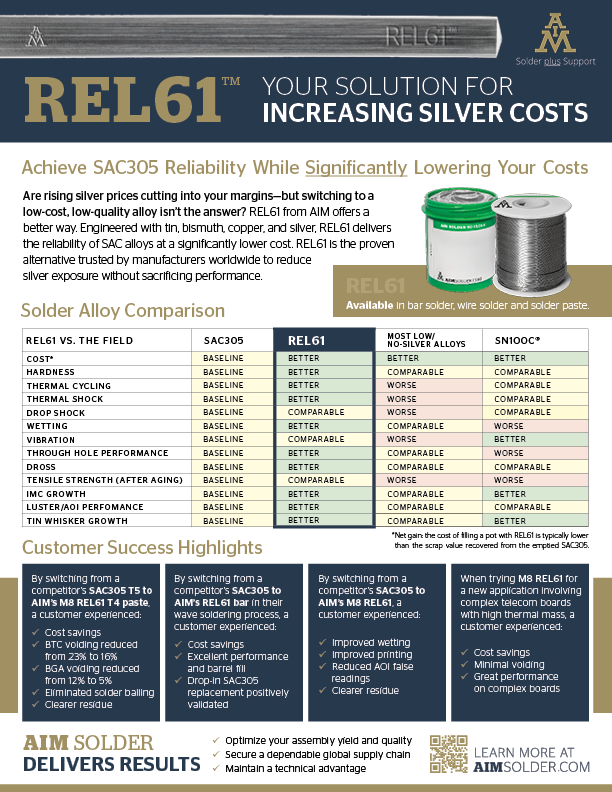

REL61™ Solution Sheet

Lower your costs without sacrificing performance. Our REL61 solution sheet details how this tin-bismuth-silver alloy delivers better through-hole performance and less dross than SAC305.

Beat the Silver Cost Surge: Why Now Is the Time to Switch from SAC305 to REL61™

See how switching from SAC305 to REL61 can cut your costs by up to 20% while actually improving solder joint reliability.