Low-temperature soldering is a rapidly developing field with several potential benefits to the electronics industry. These benefits include reduced warping of components and substrates, lower energy consumption, and reduced material costs. However, the lack of a standard solder alloy and the unique properties of emerging alloys require the development of new fluxes and processes to be successful.

In this article, we explore current challenges and opportunities in low-temperature soldering. These include the limited availability of low-temperature alloys, the disadvantages of high-bismuth alloys, the impact of additive elements on alloy properties, the need for new flux systems, and the importance of seeking guidance from solder suppliers.

What is Low-Temperature Soldering?

There is no formal definition of “low temperature” solder. However, it generally refers to alloys with peak reflow temperatures lower than those of traditional SAC305 and its variants. Whereas SAC305 has a peak reflow temperature window of 230°C to 255°C, low temperature alloys typically have peak reflow requirements of 190°C or lower. SnBi-based materials, for example, have peak reflow requirements of 170°C to 190°C.

While there are currently no standard solder alloys for low-temperature soldering, the most common ones contain bismuth. This is because other candidate elements that might contribute to lower melting points when alloyed with tin – such as cadmium, gallium, and indium – are either toxic or significantly more expensive.

What are the Advantages and Applications of Low Temperature Soldering?

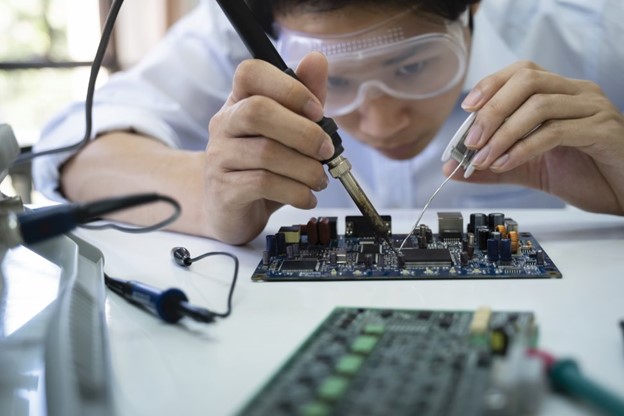

A primary application of low-temperature soldering is in surface-mount technology (SMT) for assembling electronic devices. One of the challenges of SMT is the risk of warping. Warping can occur when components are exposed to high temperatures during the soldering process. Low-temperature soldering can help mitigate this risk and improve the reliability of the interconnects.

A more complete list of low-temperature soldering benefits include:

- Reduced warping: Lower temperatures reduce component and substrate warping during assembly, which in turn reduces the risk of non-wet open (NWO) defects and improves product reliability.

- Reduced material costs: By using lower temperature solders, manufacturers can incorporate lower-cost plastics and other materials, reducing overall costs.

- Enhanced design flexibility: Low-temperature solders enable greater design flexibility, as thinner and smaller components can be used without the risk of warping during assembly.

- Reduced environmental impact: Low-temperature soldering results in reduced energy consumption and related environmental benefits, making it a more sustainable option.

- Lower processing costs: Low-temperature solders can be less expensive to process than high-temperature solders because they require less energy.

These potential benefits make low-temperature soldering a promising area for future innovation and growth. Consumer and disposable applications are likely to be early adopters due to cost advantages. However, other industries will need to carefully consider the available options, the risk/reward equation, and the resources required to develop a viable low-temperature assembly process.

What are Current Challenges in Low-Temperature Soldering?

Despite the potential benefits of low-temperature soldering, there are several challenges that must be overcome to successfully implement these materials. Some of the key challenges include:

Limited availability and lack of a standard

Currently, there are few options available for low-temperature solders, with SnBi alloys being the main option. However, SnBi alloys have several disadvantages compared to SAC-based materials, including poorer mechanical and thermal fatigue performance. This limits their potential use in certain applications and industries.

Adding trace elements and additives can improve performance and is often done to meet the requirements of a particular application. But with so many input variables, constituent elements, additive elements, and their amount and effect on solder alloy performance, a single low-temperature alloy is unlikely to meet all or even most application requirements. As a result, a “standard” has yet to emerge for low-temperature soldering.

Disadvantages of high-bismuth alloys

High-bismuth alloys exhibit brittleness which can impact both process capability and product reliability. Increasing the ratio of tin to bismuth can reduce brittleness, but this also increases the pasty range, potentially making it difficult to achieve good soldering.

While additive elements, such as silver, copper, antimony, and nickel, can improve the mechanical and thermal performance of bismuth alloys, these elements can also impact alloy ductility, melting temperature, and processing characteristics. It can be challenging to strike a balance between alloy performance and manufacturability.

Need for new flux systems

The unique properties of bismuth-bearing alloys require the development of entirely new flux systems to ensure successful soldering. The effects of surface finish, component tinning, and other soldered surfaces on these flux systems are yet to be clearly defined. These challenges highlight the need for continued research and development.

The Importance of Seeking Guidance from Solder Suppliers

It’s important to seek guidance from solder suppliers who can provide valuable insights into the available options and help manufacturers choose the right solder alloy for their specific application.

Solder suppliers can also provide guidance on the development of a viable low-temperature assembly process, including the selection of the right flux system, the optimization of process parameters, and the identification of potential risks and challenges.

Working with a reputable solder supplier can also help manufacturers stay up to date on the latest developments in low-temperature soldering and take advantage of new innovations and advancements in the field. By staying ahead of the curve, manufacturers can remain competitive and ensure that their products are optimized for performance and reliability.

Originally published in Circuits Assembly, March 2024.