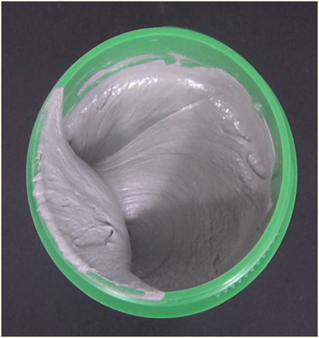

Celebrating 90 Years of Innovation, Integrity, and Partnership

In 1936, AIM began as a modest metals recycling company with a vision to meet the metal needs of the industrial world. Nine decades later, we’re proud to stand as one of the most trusted global suppliers of solder assembly materials—serving customers across industries, continents, and generations of technology.

Celebrating 90 Years of Innovation, Integrity, and Partnership Read More »